Have you ever wondered how long alum can last on your shelf? Alum, a versatile mineral compound known for its various uses, has an intriguing shelf life that may surprise you. Just like other products, the shelf life of alum can be influenced by several factors.

Anecdotal evidence suggests that the shelf life of well-stored alum is up to 3 to 10 years or even longer. Proper storage conditions, packaging, and moisture protection are just a few factors affecting alum’s stability.

In this article, we will delve into the scientific perspective behind the alum’s shelf life and provide valuable information about proper storage guidelines to maximize its longevity.

What is Alum?

Alum is a chemical compound commonly used in various industries and households. It is composed of a combination of aluminum sulfate and potassium sulfate, making it an effective ingredient for a wide range of applications.

There are different types of alum, such as potassium alum and ammonium alum, each with unique properties and uses.

Its shelf life can vary depending on the specific type and how it is stored, but generally, alum has long-lasting durability when kept in appropriate conditions.

Chemical Composition

Alum, also known as potassium aluminum sulfate, is a chemical compound with various uses due to its unique properties. Its chemical composition consists of atoms of potassium, aluminum, sulfur, and oxygen.

When dissolved in water, these atoms undergo chemical reactions that form an aqueous solution. However, like all chemicals, alum can degrade over time through processes such as oxidation or hydrolysis.

To ensure its shelf stability and maximize its usefulness, proper storage conditions are necessary.

Types of Alum

To get the most out of your alum supply, it is crucial to understand the different varieties of alum available and their unique properties. The most common types of alum are:

- Potassium Alum (Potash Alum): This is the most widely used type of alum. It has the chemical formula KAl(SO₄)₂·12H₂O. Potassium alum is often used in water purification, baking powder, and as a deodorant.

- Ammonium Alum: This type of alum has the formula NH₄Al(SO₄)₂·12H₂O. It is similar to potassium alum but contains ammonium ions instead of potassium ions. Ammonium alum is used for various industrial applications, including water treatment.

- Sodium Alum: The chemical formula for sodium alum is NaAl(SO₄)₂·12H₂O. It is less commonly encountered compared to potassium alum, but it has similar properties. Sodium alum is sometimes used in baking powder.

- Chrome Alum: This type of alum contains chromium and has the formula KCr(SO₄)₂·12H₂O. Chrome alum has applications in tanning leather, as a mordant in textile dyeing, and in the production of some types of ink.

- Ferric Alum: Ferric alum has the formula FeAl(SO₄)₃·xH₂O, and it contains iron. It is commonly used in water purification, the sizing of paper, and the textile industry.

- Ammonium Chrome Alum: This alum contains both ammonium and chromium and has the formula (NH₄)Cr(SO₄)₂·12H₂O. It is used in the tanning industry.

Industrial and Household Applications

With its wide-ranging uses in industries and households alike, alum proves to be a versatile compound that offers numerous benefits.

In the medical industry, alum is utilized as an astringent to help reduce bleeding and inflammation. Its ability to contract tissues makes it useful for treating canker sores and minor cuts.

In the textile industry, alum is used as a mordant to improve the color fastness of dyes on fabrics. It helps the dye molecules bind more tightly to the fibers, resulting in longer-lasting colors.

Alum also finds its place in food preservation by inhibiting bacterial growth and maintaining crispness in pickles and fruits.

Additionally, it has become popular among artists and crafters for its use in paper-making, bookbinding, and marbling techniques. Garden enthusiasts also utilize alum as a soil amendment to lower pH levels and promote healthier plant growth.

Factors Influencing Shelf Life of Alum

When considering the shelf life of alum, several key factors must be considered. By understanding and controlling these factors, you can ensure that your supply of alum remains stable and effective for a longer period.

Environmental Conditions

Under specific environmental conditions, alum can have a shelf life of several years. Proper storage requirements are crucial to ensuring its longevity.

Alum is sensitive to temperature changes and should be stored in a cool, dry place. Moisture content is another important factor to consider, as excessive moisture can cause clumping or degradation of the product. It is best to store alum in an airtight container to prevent exposure to humidity.

Sunlight exposure should also be minimized, as it can accelerate the breakdown of alum over time. Manufacturers conduct shelf-life testing to determine the expiration date and ensure product quality.

Packaging

To ensure its longevity, use an airtight container to store your alum in a cool, dry place and protect it from temperature changes, moisture, sunlight, and humidity. Proper packaging is crucial for preserving the quality of alum and maintaining its shelf stability.

Manufacturers employ various preservation techniques to extend the product’s lifespan. Quality control measures are implemented throughout the packaging process to ensure the alum meets all safety standards and remains in optimal condition. Additionally, product labeling provides essential information regarding storage instructions and expiration dates.

Contamination

Contamination can significantly affect the shelf stability and overall quality of alum.

To ensure a longer shelf life, it is essential to implement stringent measures for microbial growth control. Quality control procedures should be in place to detect any signs of contamination early on. This includes regular testing for microbial presence and monitoring environmental conditions that could contribute to contamination.

Additionally, manufacturers must adhere to strict hygiene practices during production and packaging. These precautions are vital in preventing any potential contamination that could compromise the effectiveness and safety of alum over time.

Hence, consumers can rely on the expiration date as an indicator of when their alum may no longer be suitable for use due to possible contamination concerns.

Shelf Life of Alum: A Scientific Perspective

In understanding the shelf life of alum from a scientific perspective, it is important to consider its chemical stability over time. Alum possesses the ability to withstand degradation and maintain its integrity for an extended period.

Chemical Stability Over Time

Alum’s shelf life can be prolonged through its chemical stability. Chemical degradation is a common concern for many products, as it can affect their overall quality and effectiveness over time.

However, alum has shown remarkable resistance to this deterioration process. Its chemical composition remains stable even under varying storage conditions, such as temperature and humidity.

This ensures that the product maintains its shelf stability for an extended period. Alum’s chemical stability guarantees consistent performance, making it a reliable choice for various applications. Whether used in cooking, medicine, or industrial processes, you can trust that alum will retain its properties and effectiveness throughout its shelf life.

Reaction with Air, Water, and Other Substances

Alum is known for its chemical reactivity, which can lead to degradation over time if it is not stored correctly. One common reaction that occurs is oxidation, where alum reacts with oxygen in the air. This can result in a change in the color or texture of the product.

Another reaction that takes place is hydration, where alum absorbs water molecules from its surroundings. This can cause clumping or caking of the product if it is exposed to high-humidity environments.

Storing alum in airtight containers and away from moisture is crucial to minimize these reactions and ensure its long-term stability.

pH Levels and Their Impact

The pH level of alum can significantly impact its chemical stability and reactivity with other substances. Alum is most stable in a slightly acidic to neutral environment, with a pH range of 4 to 7. If the pH becomes too low or too high, it can adversely affect the integrity of alum and lead to decomposition or loss of effectiveness.

To ensure storage safety, storing alum in appropriate containers resistant to corrosion and leakage is essential. Keeping alum away from moisture and extreme temperatures can also help maintain its stability over time.

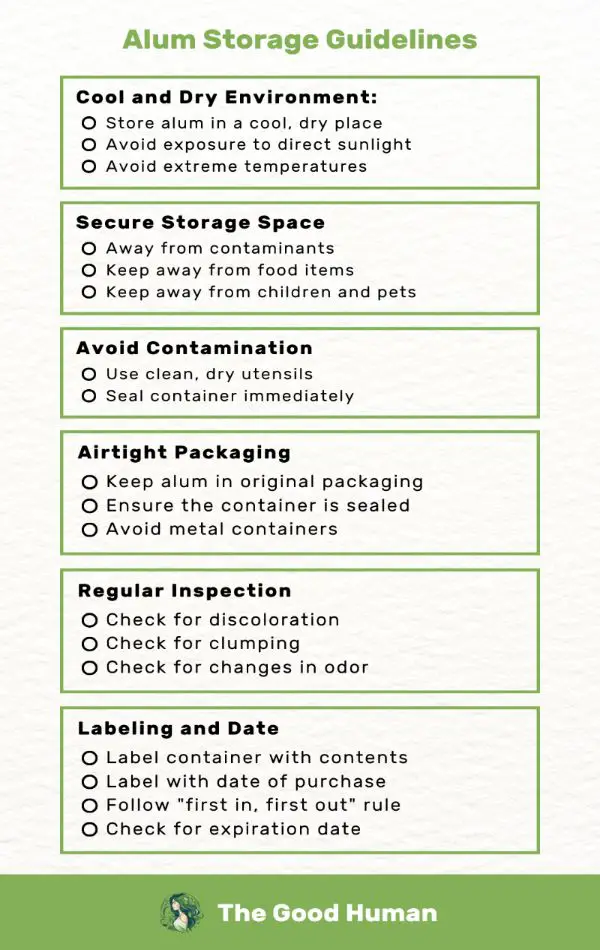

Alum Storage Guidelines

There are a few important guidelines to keep in mind when it comes to storing alum.

Proper Storage Conditions

Make sure you store alum in a cool, dry place to ensure its maximum shelf life. The storage temperature should be between 50°F and 70°F, as higher temperatures can accelerate the degradation process.

Humidity levels should be kept low, ideally below 50%, to prevent moisture absorption, which can lead to clumping or caking of the alum crystals.

Protecting alum from light exposure is essential, as UV radiation can cause chemical reactions that reduce effectiveness over time. Additionally, proper air circulation is crucial to maintaining the quality of alum. Ensure enough ventilation in the storage area to prevent any buildup of moisture or odors.

Appropriate Containers and Packaging

To ensure your alum stays fresh and potent, storing it in suitable containers and packaging that protect it from light, moisture, and air is crucial. When selecting appropriate storage materials, consider using opaque containers made of glass or plastic with tight-sealing lids. These containers should be impermeable to prevent any moisture or air from entering.

Also, choose packaging materials that provide extra protection against light exposure. Proper packaging is crucial for maintaining the shelf stability of alum by reducing external factor-caused degradation.

Shelf life testing is conducted to determine the optimal shelf life of alum under different storage conditions. This involves subjecting samples to various environmental conditions, such as temperature and humidity, over an extended period. Through this testing, manufacturers can establish guidelines on how long the product remains effective and safe when stored correctly.

Disposal of Expired Alum

Proper disposal of expired alum is essential for maintaining environmental safety and preventing potential harm. When it comes to disposing of expired alum, there are several methods you can consider.

One option is to contact your local waste management facility or recycling center to inquire about their specific guidelines for disposing of chemicals like alum. They may have specific regulations in place that you need to follow.

Another option is to look into recycling options for alum. Some facilities specialize in recycling certain chemicals, and they may be able to accept expired alum for proper treatment and reuse.

It is important to remember that improper disposal can have significant environmental impacts, including contamination of water sources and soil. Additionally, the health hazards associated with improper disposal should not be taken lightly, as they can pose risks for humans and other living organisms.

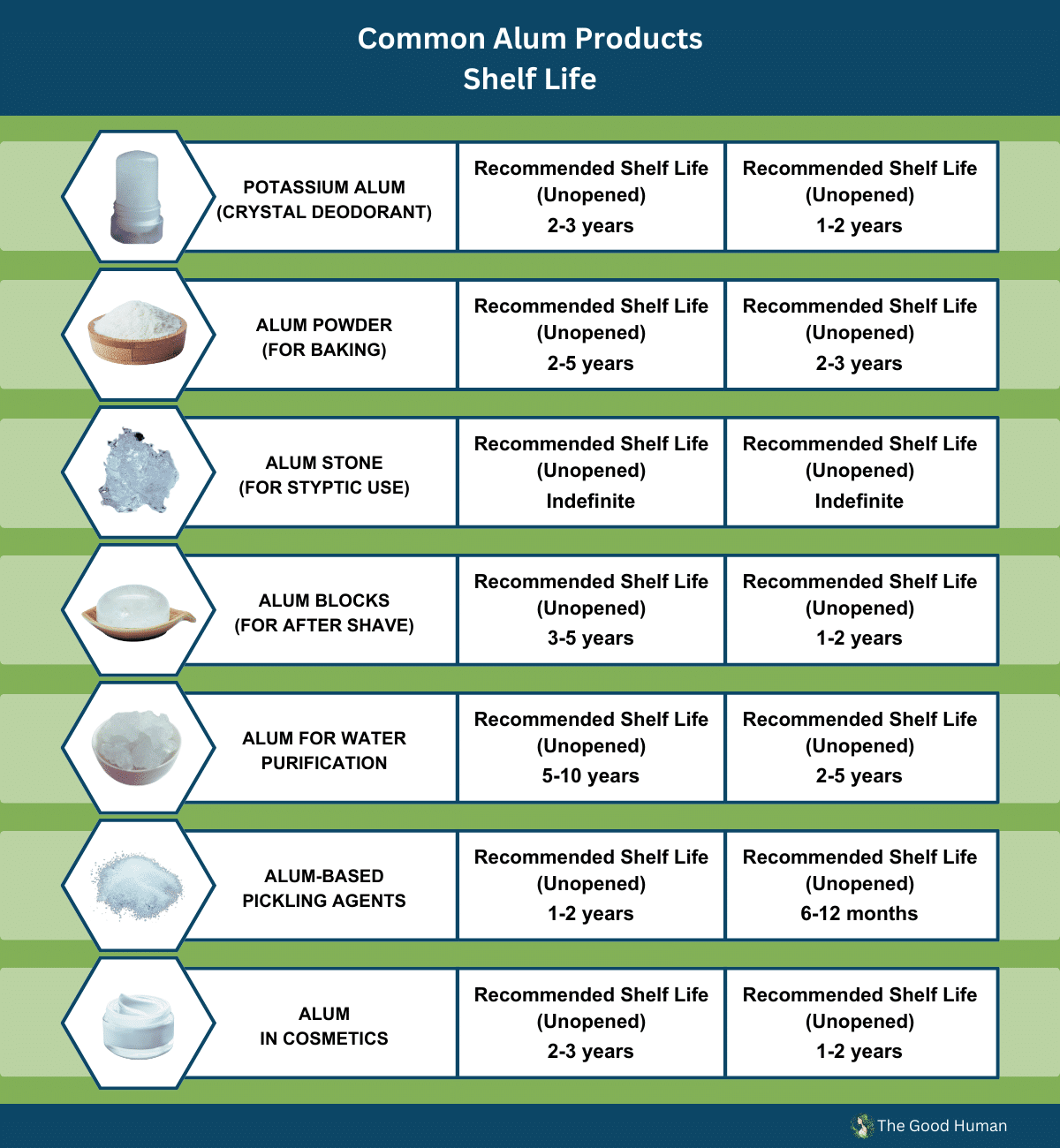

Common Alum Products and Their Shelf Life

In culinary applications, alum is commonly used as a food additive for pickling and crisping fruits and vegetables. In water treatment, alum is often used as a coagulant to remove impurities from drinking water, such as suspended particles and organic matter.

In cosmetics and personal care products, alum can be found in deodorants, aftershaves, and antiperspirants due to its ability to inhibit the growth of odor-causing bacteria. The shelf life of these products may vary depending on their formulation and packaging.

Alum in Culinary Applications

Alum is commonly used in culinary applications for its flavor-enhancing properties. It can add a tangy and slightly acidic taste to pickles, fruits, and vegetables. Furthermore, alum has been known to provide various health benefits, such as aiding digestion and reducing inflammation.

However, it is important to note that alum should be used in moderation, as excessive consumption may lead to potential side effects like stomach upset or constipation. The recommended dosage for culinary purposes is typically very small, usually less than 1/8 teaspoon per recipe.

Alum in Water Treatment

Alum is a game-changer in purifying water and ensuring clean and safe drinking water for communities in need. It has been widely used as a coagulant in water treatment processes due to its ability to remove impurities and particles from the water.

Alum works by attracting and binding with the suspended particles, forming larger flocs that can easily settle or be filtered out. However, it is essential to note that alum toxicity can occur if consumed in large quantities or over a long time. This has led researchers to explore alternatives to alum in water treatment, such as ferric chloride and poly aluminum chloride.

Additionally, while alum dosage varies depending on the quality of the water being treated, side effects are generally minimal when used within recommended levels.

Alum in Beauty and Personal Care Products

Alum has been used for centuries in skincare due to its astringent properties. It helps tighten the skin, reducing the appearance of pores and giving it a smoother complexion.

Alum can act as a natural styling agent in hair care by providing texture and hold to your hair. It is also commonly found in deodorants as it has antimicrobial properties that help control body odor.

Beyond beauty products, alum has also been used in natural remedies and traditional medicine for various purposes, such as treating canker sores or mouth ulcers.

Can Alum Expire?

If alum expires, its effectiveness may be reduced, and it may not work as effectively in various applications such as pickling or tanning. It is always recommended to use fresh alum for the best results.

How to Check Alum for Spoilage

One simple way to determine if your alum has spoiled is by using your senses: look for any discoloration, smell for any unusual odors, and taste a small amount to check for off-flavors.

Alum can last indefinitely if stored properly. However, it may lose its effectiveness and quality over time. Checking the appearance of alum is important; any discoloration or presence of mold indicates spoilage.

Unusual odors, such as a strong ammonia smell or a musty scent, are also signs that the alum has gone bad. Additionally, tasting a small amount can help identify any off-flavors that may have developed due to spoilage.

It is also recommended to check the expiration date on the packaging before use.

What Happens if Alum Expires?

If your alum has expired, it can lose its effectiveness and may not work as effectively for the desired purpose. The impact of expiration on alum is that its chemical properties begin to degrade over time, reducing its ability to act as a preservative or clarify water.

The effects of using expired alum can include reduced clarity in treated water, decreased shelf life of preserved foods, and compromised antimicrobial activity.

Using expired alum can also be dangerous, as it may not provide the intended benefits and could potentially harbor harmful microorganisms.

Extending the Shelf Life of Alum

Alum’s shelf life can be stretched like a rubber band with proper storage. To extend the shelf life of alum, it is crucial to employ effective preservation techniques.

The first important factor to consider is the storage temperature. Alum should be stored in a cool, dry place, away from direct sunlight and high temperatures. Heat can accelerate chemical reactions, leading to a decrease in its quality over time.

Furthermore, humidity control is essential to maintaining the integrity of alum. Excessive moisture can cause clumping or caking, rendering it less effective.

Another aspect to focus on is microbial contamination prevention. Alum should be kept in an airtight container to minimize exposure to bacteria and other microorganisms that could degrade its quality. Regularly inspecting the container for any signs of spoilage or mold growth is also recommended.

Remember that proper storage practices are key to preserving the quality and potency of alum over an extended period.

Preserving Potency: Mastering Alum Storage for Longevity

In conclusion, the shelf life of alum can vary depending on factors such as storage conditions and product quality. However, with proper storage guidelines, alum can maintain its effectiveness for an extended period.

It is vital to store alum in a cool, dry place away from moisture and direct sunlight to prevent degradation. Following these guidelines ensures that your alum products remain effective and reliable for their intended uses.